INTERNATIONAL CONSTRUCTION CONSORTIUM

Q: International Construction Consortium (ICC) is currently in its fifth decade of operations. Can you describe your corporate philosophy?

Q: International Construction Consortium (ICC) is currently in its fifth decade of operations. Can you describe your corporate philosophy?

A: ICC is a brand that’s synonymous with exceptional standards and international quality. We are driven by our philosophy to revolutionise Sri Lanka’s construction landscape – while supporting all direct and indirect stakeholders – via best in class products and technology, which in turn increases customers’ returns on investment.

Affirmed as a CS2 Grade, ISO 9001, ISO 14001 and ISO 45001 certified construction company, we’re driven by the need to expand the industry by catering to unmet needs.

As a leading precast manufacturer in the country, ICC has pioneered the introduction of engineering solutions covering the three main components of construction – viz. materials, labour and time. Armed with expertise and experience across a range of construction projects, our portfolio of technologies and products is aimed at reducing these components, both effectively and efficiently.

Q: Could you outline some of your latest innovations?

A: Over the past few years, many products have been introduced to Sri Lanka to minimise the use of materials and labour, and construction time.

For instance, ICC Acotec precast wall panels – manufactured using European technology from ELEMATIC Finland – are used to partition medium and high-rise buildings by replacing conventional materials.

First introduced in the late 1980s, this system has proven itself in more than 15 countries for being five times faster than conventional brick and block construction. Extending our expertise and strengths in this domain, we have established two precast yards in Piliyandala and Galkulama.

ICC Timber is another innovation. Designed for classic wood flooring, this revolutionary method promotes quick and simple DIY installation systems by providing a range of modern prefinished flooring solutions that reduce lead times, and eliminate stressful fitting and fixing.

The latest addition to the ICC portfolio is ICC Smart Eco Solutions, which carries a range of organic waste composting machines, and modular wastewater and sewage treatment plants. The composting machines convert domestic and commercial organic waste into fertiliser within 24 hours, while the industrial sewage treatment and wastewater management system is an ideal solution for the waste-related challenges facing Sri Lanka.

Q: And what does ICC have planned for 2022?

Q: And what does ICC have planned for 2022?

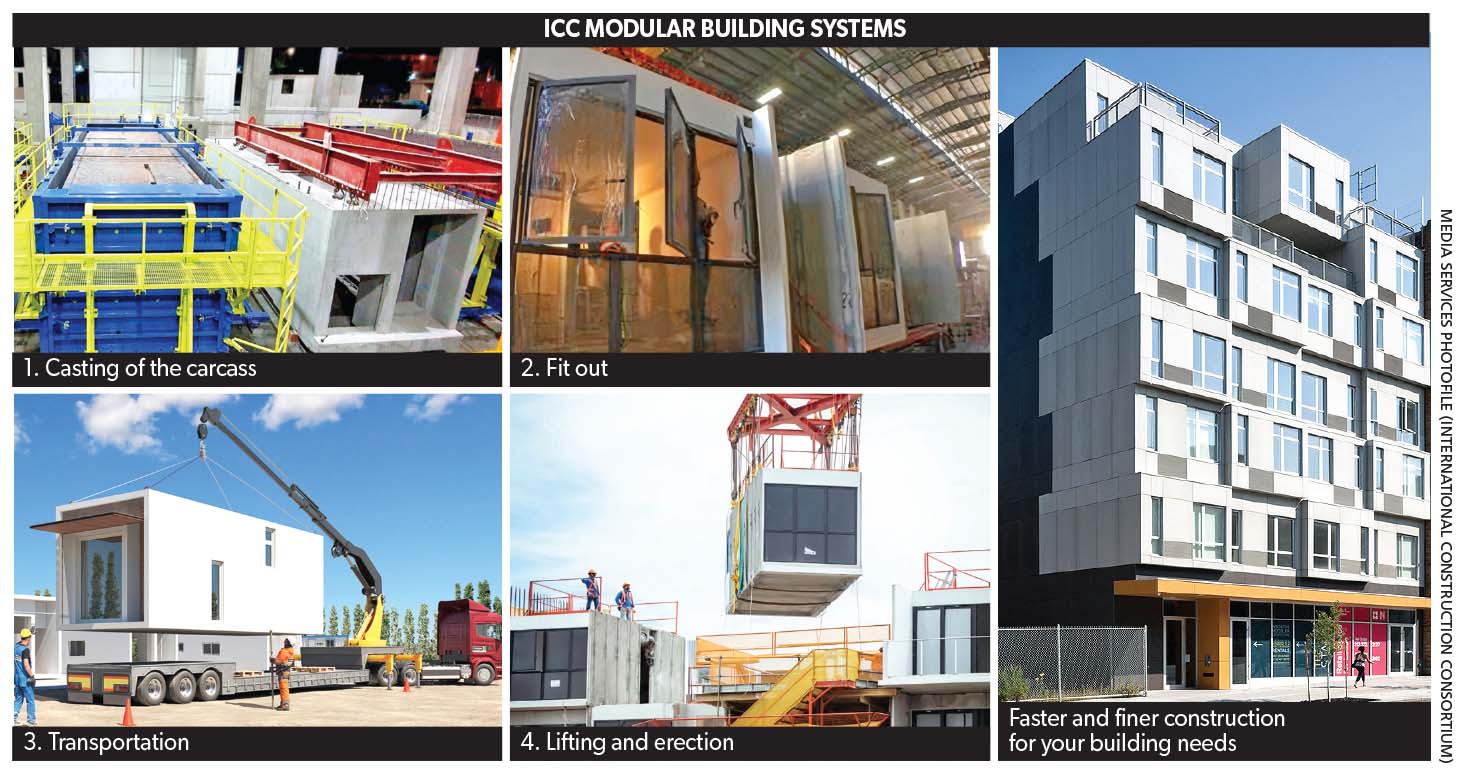

A: We are excited to announce our latest venture – Prefabricated Prefinished Volumetric Construction (PPVC). One of the most advanced modular construction technologies, this system has the potential to resolve labour and material shortages in the construction industry to a great extent.

PPVC has been widely adopted in low, medium and high-rise buildings throughout the world, especially in densely populated countries like Singapore, the USA, Malaysia and the Maldives.

As a forward-thinking civil engineering firm, we are driven to promote sustainable construction.

With PPVC, we’re able to reduce the labour and construction time required onsite, by fabricating and finishing more work offsite. This ensures a safer and more conducive work environment with minimal impact on surrounding living spaces. It also minimises wastage, which reduces the carbon footprint.

The norms of modular building solutions imply the use of PPVC technology to facilitate offsite fabrication with components made of multiple units, completed with internal finishes, fixtures and fittings, transported to infrastructure sites and installed in a Lego-like manner.

However, ICC has taken a step forward in this sphere by transforming construction technology from 2D to 3D integration via PPVC.

Q: What are the added benefits of PPVC for your stakeholders and the industry as a whole?

A: Given the product’s many unique qualities, including time and cost savings, it would be the industry’s most obvious and sustainable choice. Since this advanced technology calls for less manual labour, it suits today’s economic climate and the pandemic-induced volatility.

As for stakeholders, PPVC offers a significant advantage to developers and investors as there is less waiting time for investment returns, and a higher turnover of projects.

As for stakeholders, PPVC offers a significant advantage to developers and investors as there is less waiting time for investment returns, and a higher turnover of projects.

Catering to the need for sustainable and environmental-friendly construction solutions, this technology can facilitate the customisation of products for varying appearances, building types and sizes, while maintaining precision and higher quality.

Architects will find enhanced flexibility through PPVC, allowing products, structures and shapes to be easily combined and personalised according to client requirements.

And given that structures configured using PPVC technology have clearly defined performance metrics, and a clear set of guidelines for bracing a building, structural engineers now have an easy, safe and dependable system of design.

Q: What else does the company have in store for 2022?

A: We’ve accumulated a plethora of expertise in multidisciplinary construction projects – so we’re passionate about expanding our horizons in terms of products and technologies.

Our research and development team is dedicated to studying the latest innovative and sustainable construction

trends across the globe, and finding ways to adapt them to the local construction environment.