ZERO WASTE

WASTE PRODUCTS

Sustainability via Zero Waste

BY Kiran Dhanapala

Mahatma Gandhi noted that “there is enough in the world for everyone’s need but not enough for everyone’s greed.” Sustainability has numerous zero targets and this includes Zero Waste, which is required for a sustainable society. This concept is a fundamental part of the necessary transition to a circular economy.

The Zero Waste definition that was adopted by the Zero Waste International Alliance in 2018 is as follows: “The conservation of all resources by means of responsible production, consumption, reuse and recovery of products, packaging and materials without burning, and with no discharges to land, water or air that threaten the environment or human health.”

There is a hierarchy of progressive measures of policies and strategies, to support the Zero Waste system from highest and best to lowest use of materials. It is known as the Zero Waste Hierarchy and shaped like an inverted triangle.

From top to bottom, the triangle of issues to address include rethink or redesign, reduce, reuse, recycle or compost, material recovery, residuals management and the unacceptable – e.g. disallowing the incineration of discards, toxic residues in consumer products or building materials.

Being environmentally-friendly may not always be straightforward. Is it humanly possible to be really Zero Waste for business operations? What if something cannot be recycled or repurposed, or there’s insufficient infrastructure to do so?

Given these challenges, it is commonly accepted that getting within two percent of Zero Waste – or diverting 98 percent of waste through reducing, recycling or reusing – fits the definition.

As with all resource efficiency reduction measures, there are diminishing marginal returns – meaning that it is easier and cost effective initially, and then becomes more expensive and challenging. Most business manufacturers can achieve 80 percent of diversion from landfill but the last 10-20 percent is challenging. This stems mostly from inconsistencies around recycling infrastructure in the world.

So what alternatives can businesses use to rely less on landfills and benefit the environment?

For example, s olar panels generate clean energy but the early use of such panels will also generate as much as eight million metric tons of e-waste by 2030. This can end up in landfills if not recycled.

olar panels generate clean energy but the early use of such panels will also generate as much as eight million metric tons of e-waste by 2030. This can end up in landfills if not recycled.

Exporting or incinerating waste is not a solution. First Solar is a US company that’s making a change by adopting integrated circularity in the design of its solar panels. It disassembles and recycles old panels, recovering 90 percent of the materials inside.

Many companies begin their zero waste journey by taking on one waste stream initially and working on its supply chain.

For instance, Body Shop is reportedly on track to source 500 metric tons of plastic gathered by waste pickers for packaging this year. Through its partnership with Indian organisation Plastics for Change, it purchases Fairtrade certified recycled plastic collected by Indian waste pickers.

This facilitates a better livelihood for waste pickers and prevents the plastic from ending up in landfills and oceans. The waste is collected and sorted in centres, and then cleaned, compressed into bales and exported to Europe. It is converted, cleaned and sterilised into food grade standard, then converted into granules and recycled back into Body Shop bottles.

It took the company five years to build up the plastic waste raw material supply chain for its needs.

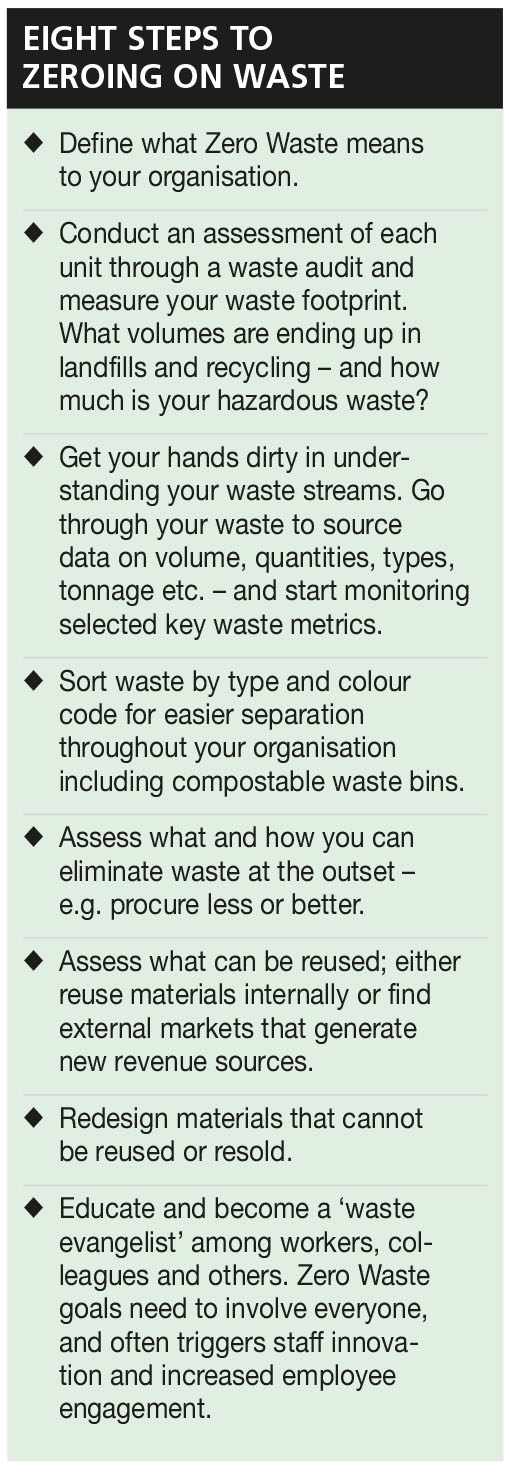

What’s key in beginning the Zero Waste journey is to clearly define what your organisation is aiming for and conduct a waste audit. Set target goals and dates, with interim goals and dates – preferably publicly to demonstrate accountability and transparency.

It’s also important to transform organisational culture so that staff can lead these efforts as they know the business best.

Leave a comment